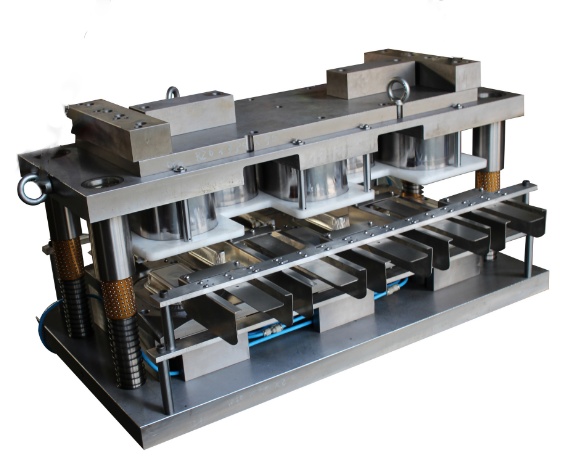

Customize Mold:

1 out of 5 molds as shown:

Calculate without considering depreciation:

1 out of 5 molds with 60 times per minute as an example;

It can produce 300 lunch boxes per minute and produce 20 hours per day. The output is:

20*60*300=360000(s) 360,000 (days)

Product standard weight is 5g (pieces), according to the calculation of the consumption of aluminum foil:

2070KG (waste edge rate of 15%: 5g * 0.15 = 0.75 * 360000)

actual consumption of aluminum foil total of 2.07 tons, resulting in aluminum foil scrap is 270KG; (The waste is 80% of the price of aluminum ingots!)

1512 product processing fee is 12000/ton, after deducting the cost of factory hydropower labor (the cost varies from place to place), this set of molds can recover the manufacturing cost in about six months.

Mold Material Selection:

High quality steel: Cr12MoV,

Cr12, DC53 SKD11, etc.;

The mold is suitable for aluminum foil material alloy: 8011, 3003, 8006, 3005, etc.;

Thickness: 0.03 mm ~ 0.35 mm;

Type: ordinary foil, lubricating foil, paint foil, etc.;

Technical data: elongation ≥12%, tensile strength ≥120 mpa

We have our own workshop! Produce high quality molds; our molds have long-term quality assurance, stable quality, high precision and reasonable design. The mold can realize the processes of cutting, forming, sealing, rolling and the like of the aluminum foil product.

1. The mold is made according to your requirements to make specifications and sizes;

2. Customized with special design and logo;

3. Optimization of project hemming and hemming performance;

4. The steel used in the key parts is the best mold steel;