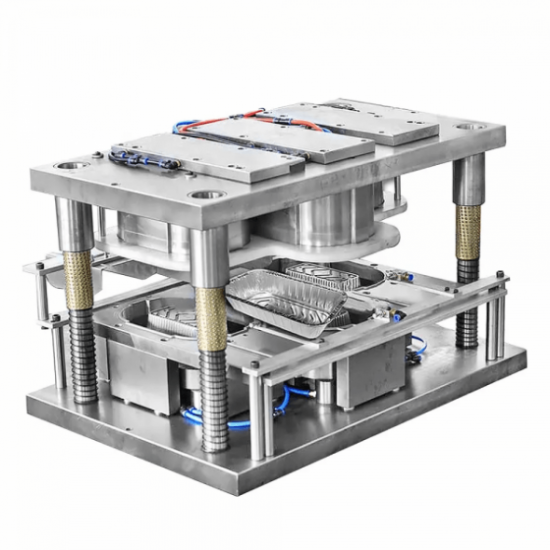

Aluminum Foil Container Mould 2 Cavity

INTRODUCTION

Aluminum foil container mould 2 Cavity is used to form raw material into container shape precisely. The production capacity is 100-120 pcs per min.

FEATURE

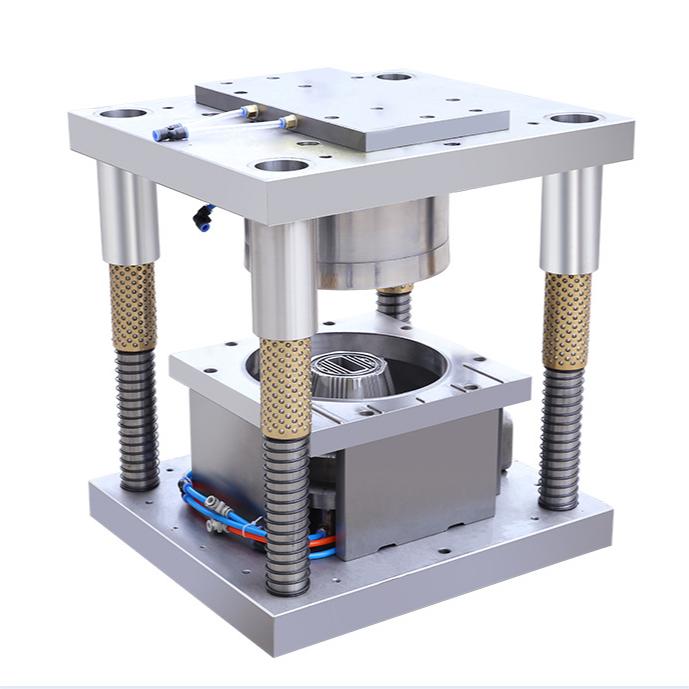

- Made of imported high-quality mould steel. Mold Core is made of DC-53, SKD11 mould steel from Japan.

- With the flexibility of gas, it adopts the principle of gas compression and rebound, high precision, more stable.

- Manufactured with best heat treatment and WEDM-LS process, with high processing accuracy within 0.005mm.

- The processing of aluminum foil containers is completed from cutting, stretching, forming, curling, and finished products at one time, including various sides (G side, L side or IVC, folding side, etc.).

Whether you require modifications to size, capacity, functionality, or automation features of aluminum foil container mould 2 Cavity, our team of experts works closely with you to design and manufacture a machine that precisely fits your production goals.

Our production line and aluminum foil container mould 2 Cavity enhance productivity and streamline operations, but it also offers reliability. Built to last, our machines are durable and designed for continuous performance, minimizing downtime, and allowing you to meet your production targets consistently. Our molds use mold steel imported from Japan to ensure stable use for up to ten years