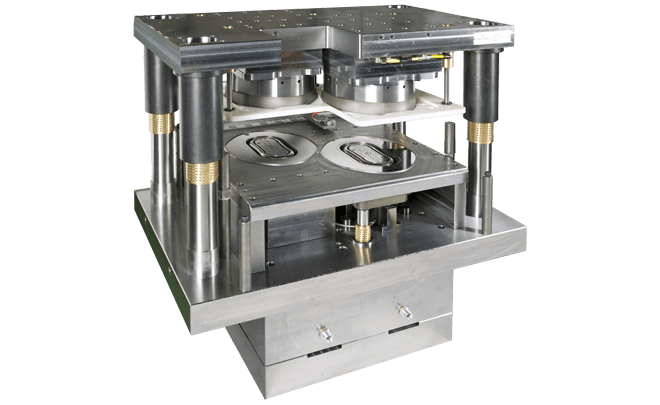

Smooth Wall Aluminum Foil Container Mould

INTRODUCTION

There are two kinds of mould to make different kinds of containers: Smooth wall and Wrinkle wall.

Smooth wall aluminum foil container moulds are specially designed moulds used in the production of smooth wall aluminum foil containers. These moulds are used in the manufacturing process to shape and form the aluminum foil into the desired container shape.

The moulds for smooth wall aluminum foil containers are typically made from high-quality materials such as DC53, SKD11, CR12MOV. They are precision-engineered to ensure accurate and consistent shaping of the aluminum foil.

FEATURE

- Made of imported high-quality mould steel. Mould Core is made of DC-53, SKD11 mould steel from Japan.

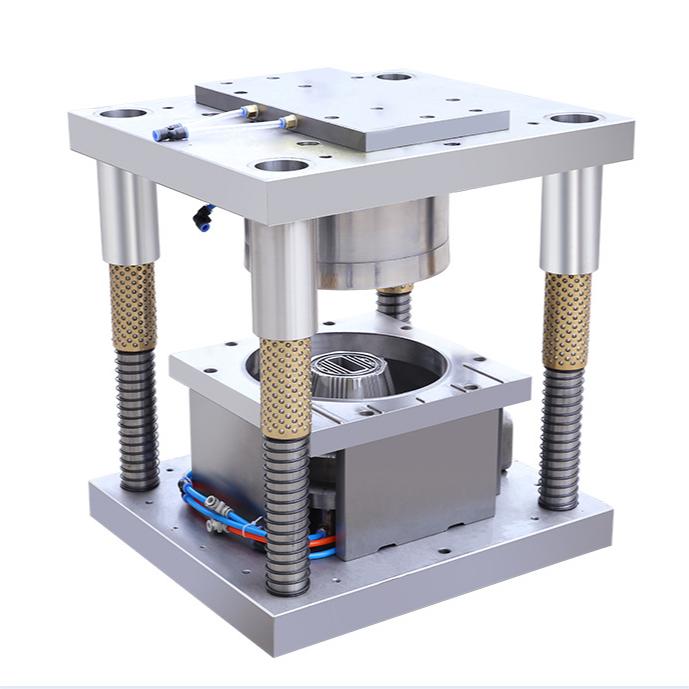

- With the flexibility of gas, it adopts the principle of gas compression and rebound, high precision, more stable.

- Manufactured with best heat treatment and WEDM-LS process, with high processing accuracy within 0.005mm.

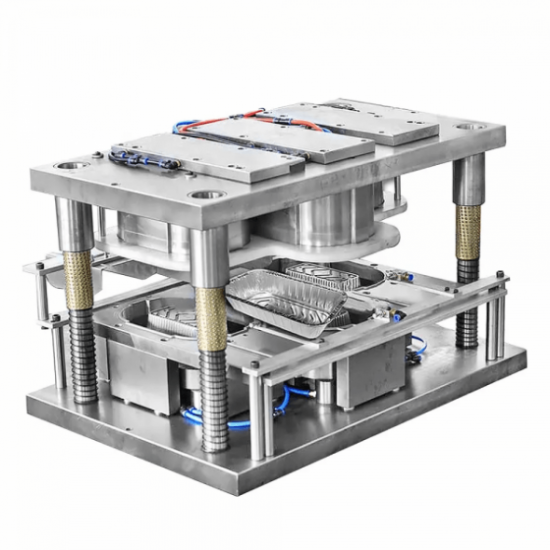

- The processing of aluminum foil containers is completed from cutting, stretching, forming, curling, and finished products at one time, including various sides (G side, L side or IVC, folding side, etc.).

WHY CHOOSE OUR MOULD

Whether you require modifications to size, capacity, functionality, or automation features of aluminum foil container mould, our team of experts works closely with you to design and manufacture a machine that precisely fits your production goals.

Our production line and aluminum foil container mould enhance productivity and streamline operations, but it also offers reliability. Built to last, our machines are durable and designed for continuous performance, minimizing downtime, and allowing you to meet your production targets consistently. Our moulds use mould steel imported from Japan to ensure stable use for up to ten years

The mould design may vary depending on the specific container shape and size requirements. It typically consists of two parts: the male mould and the female mould. The male mould is the upper part that shapes the top of the container, while the female mould is the lower part that shapes the bottom of the container.

During the production process, the aluminum foil is placed between the male and female moulds, and pressure is applied to shape the foil into the desired container shape. The moulds may also have additional features or mechanisms for trimming excess foil or creating specific patterns or embossing on the container surface.

It’s worth noting that specific details and designs of smooth wall aluminum foil container moulds may vary depending on the manufacturer and the specific requirements of the containers being produced.