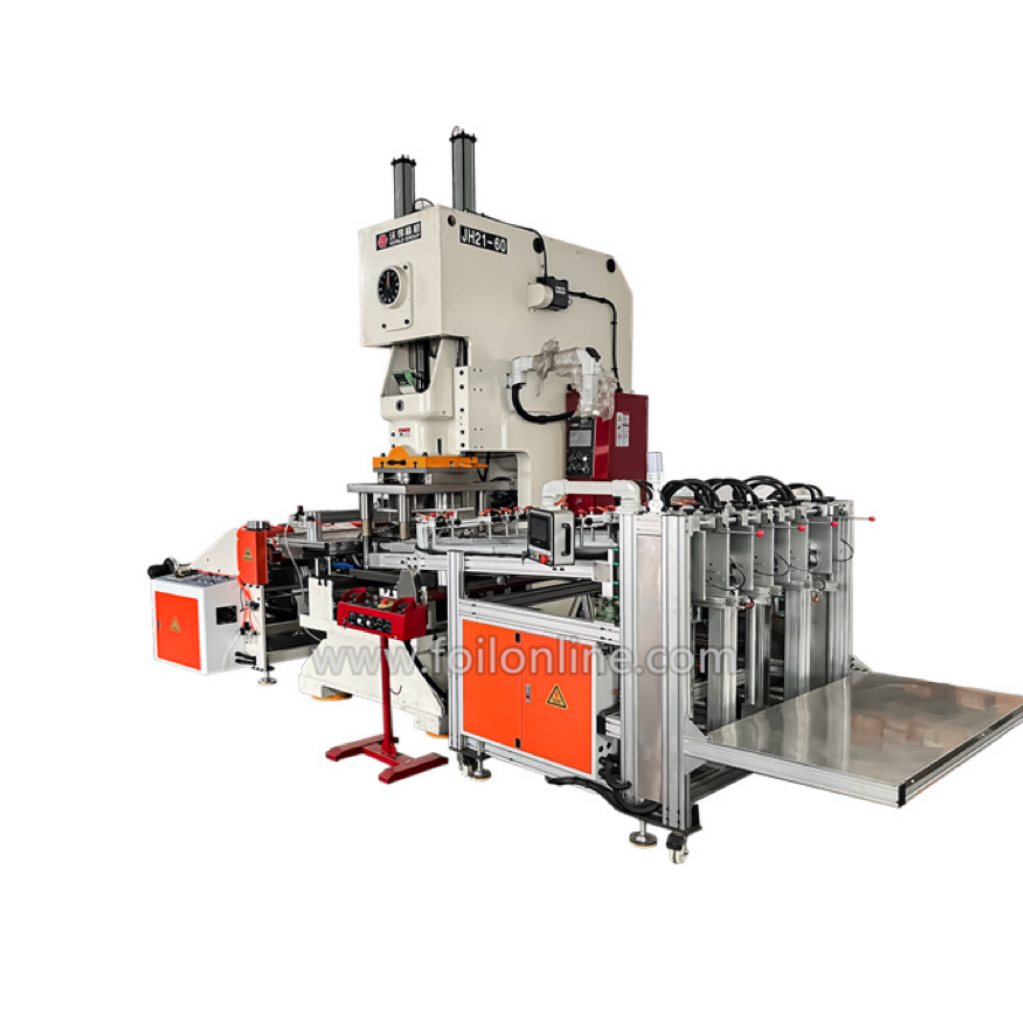

Aluminum Foil Tray Making Machine

Aluminum Foil Tray Making Machine

INTRODUCTION

KONIX aluminum foil tray making machine is a special equipment used to manufacture aluminum foil trays or containers. These machines are commonly used in the food packaging industry to produce disposable trays for various applications, such as takeout containers, airline meal trays, and catering trays.

FEATURE

- This production line can work automatically. Worker operates the machine through electric control system and collect the stacked products conveniently.

- Machine can be designed and manufactured according to customer’s requirment and customer’s target price.

- Top Safety and long lifetime,high precision control of feeding step and speed.

- Wet clutch pneumatic punch, long service life, low noise

- The replacement of the mold is convenient and easy to change.

CONFIGURATION

- Auto-lubricated Foil Feeder

- Pneumatic Press

- Foil tray mould

- Capsules Stacker

- System control touch screen

- Foil Scrap System

- Electric cabinet

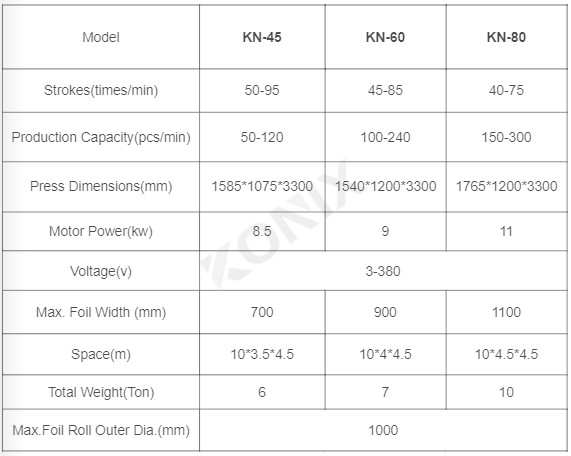

Production Capacity

The capacity of production of konix aluminum foil tray could vary from 50 – 300 pcs/min

Production Flow of Fully Automatic Aluminium Foil Tray Making Machine

- The feeder feeds the material into the pneumatic press.

- The material goes into the mold and is pressed into shape.

- Products are made and blown out

- Products are collected by stacker

TECHNICAL DATA

KONIX provides one-stop solution for aluminum foil tray production line including aluminum foil tray mould.

The aluminum foil tray making machine typically follows a series of steps to produce the trays. Here’s a general overview of the process:

- Aluminum foil roll feeding: The machine starts by feeding the aluminum foil roll into the machine. The roll can be of different widths and thicknesses, depending on the desired tray specifications.

- Foil roll unwinding: The machine unwinds the aluminum foil roll, ensuring a continuous supply of foil for the manufacturing process.

- Foil roll tensioning: The foil is properly tensioned to ensure smooth and accurate feeding.

- Foil lubrication: A lubricant or release agent is applied to the foil surface to prevent sticking and facilitate the forming process.

- Foil heating: The machine applies heat to the aluminum foil, softening it and making it more pliable for forming.

- Tray forming: The machine uses a combination of mechanical and pneumatic actions to form the aluminum foil into the desired tray shape. This process can involve pressing, folding, and cutting the foil.

- Tray stacking and counting: Once the trays are formed, the machine can stack them in a designated pattern and count the number of trays produced.

- Optional features: Some aluminum foil tray making machines may include additional features, such as punching holes for ventilation or embossing designs or logos onto the trays.

""

1