Automatic Aluminium Foil Container Making Machine KN-60/63T

Leading Manufacturer Of Fully Automatic Aluminium Foil Container Making Machine, which is High Speed Professional Production Line.

Fully Automatic Aluminium Foil Container Machine

Production capacity is customized according to the size of container and different specification of machine from 60-300pcs per minute.

60Ton: normally equipped with 3 cavities mould by150~180pcs/min,about 72k pcs/8 hours

|

Brand: KONIX Strokes: 40-75 times/min Voltage: 3-380V Press Dimension: 1.3*2.1*3.3mm Expansion Shaft: Ø3 inch/6 inch Max.Foil Roll Outer Dia: ≥Ø700mm Max.Foil Width: 1300mm Length of Strokes: 250/220mm Working Table Dimension: 1300*1000mm Max.Mould Dimension: 1200*900mm Closed Height: 370-450mm Slide Area Dimension: 320*145mm 4-Ø18 / 320*245mm 4-Ø18 |

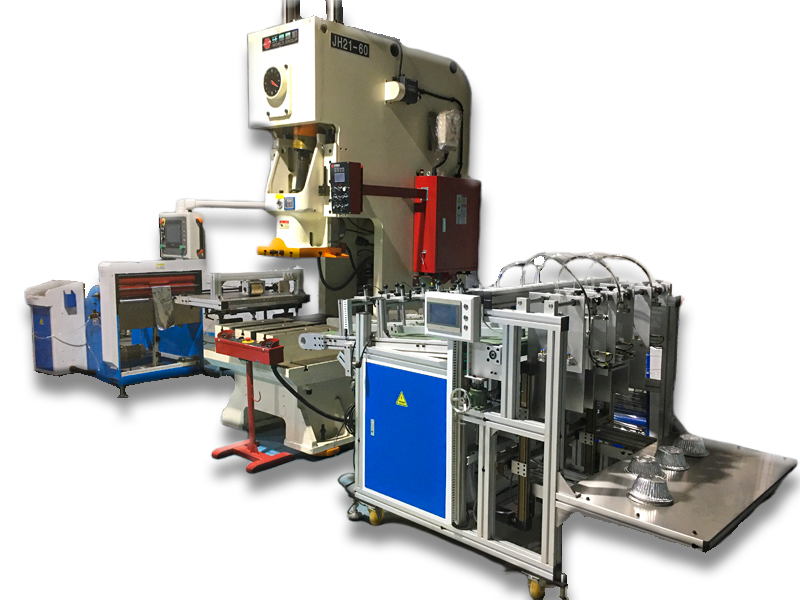

A. Aluminium Foil Container Making Machine Composition

Auto-lubricated Foil Feeder with Feeding Head Frame

1. Unwind foil

2. Coating foil with oil automatically

3. Feeding Material and detect automatically with Double servo synchronous feeding

4. equipped with planetary reducer, high feeding precision, no bias, more stable.

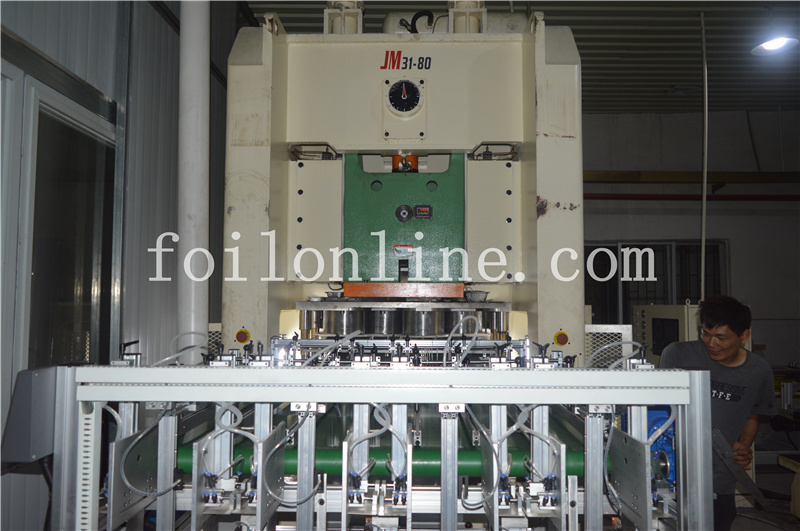

Pneumatic Press Machine

equipped with system control touch screen

1. It adopts spur gears and oil-immersed lubrication

2. high meshing precision,

3. stable transmission, low noise

4. large load-carrying capacity

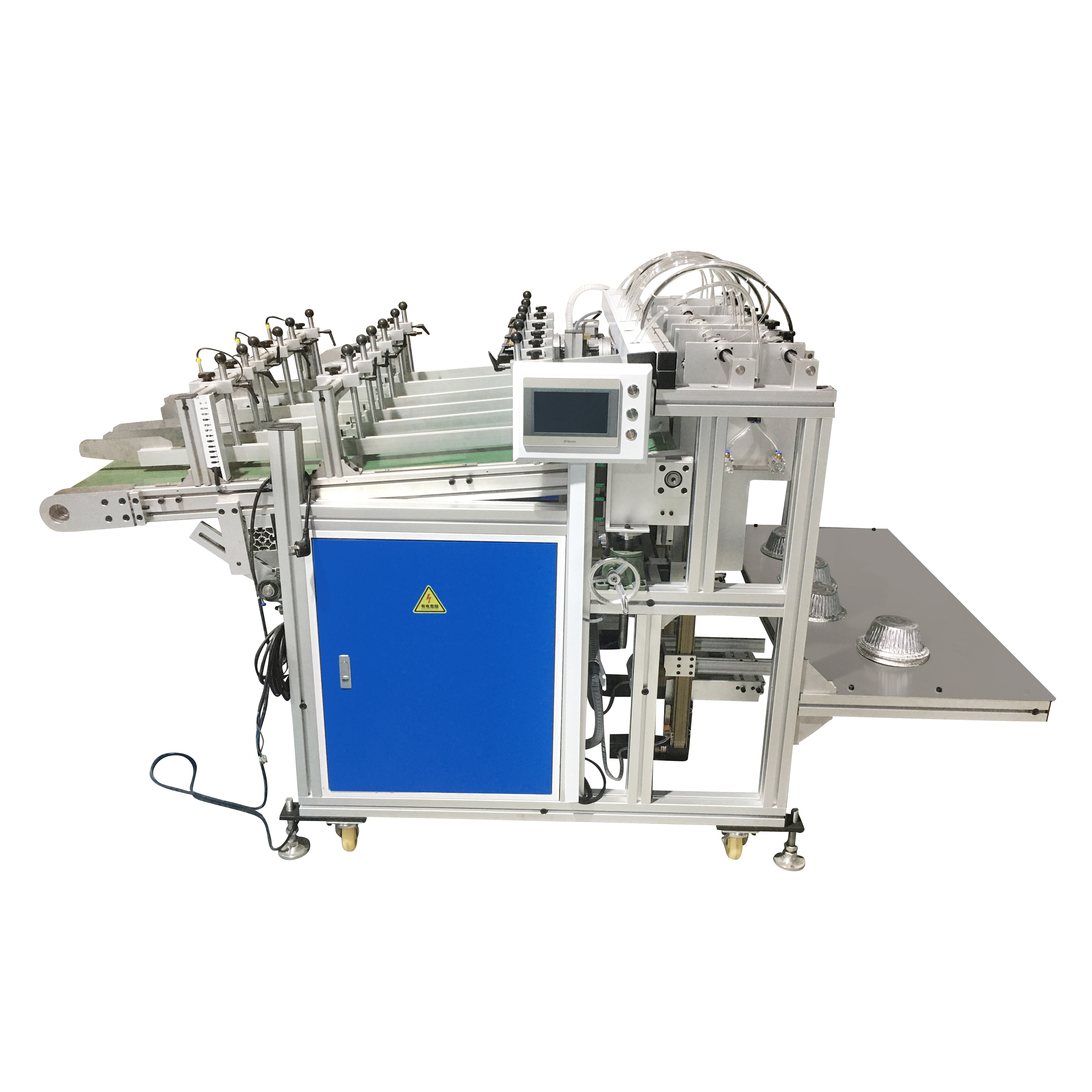

Stacker

1. Controlled by PLC Control Touch Screen

2. Accurate response with Servo Motor

3. Speed can be adjusted and displayed on the Panel with converter

4. Stable and corrosion-proof body by high-quality aluminum alloy.

5. Products size & dimension can be adjusted

6. Products be collected and calculated automatically

Container Mould

1. Made from imported high-quality mold steel.

2. Longer service life, high precision, more stable quality by using pneumatic technology

3. Customizable according to different customer needs. The forming process can be completed from cutting, stretching, forming, curling at one time, including various sides (G side, L side or IVC, folding side, etc.)., or special treatment (special electroplating treatment or nano treatment)

B. Production Flow of Aluminium Foil Container Making Machine

Decoil– Oil Lubrication – Aluminium Foil Feeding – Press Stamping – Automatic Collection

1) The feeder feeds the material into the pneumatic press.

2) The material goes into the mold and is pressed into shape.

3) Products are made and blown out to stacker

4) Products are counted and collected automatically by stacker