Fully Automatic Aluminium Foil Container Making Machine

Leading Manufacturer Of Fully Automatic Aluminium Foil Container Making Machine, which is High Speed Professional Production Line.

Fully Automatic Aluminium Foil Container Making Machine

INTRODUCTION

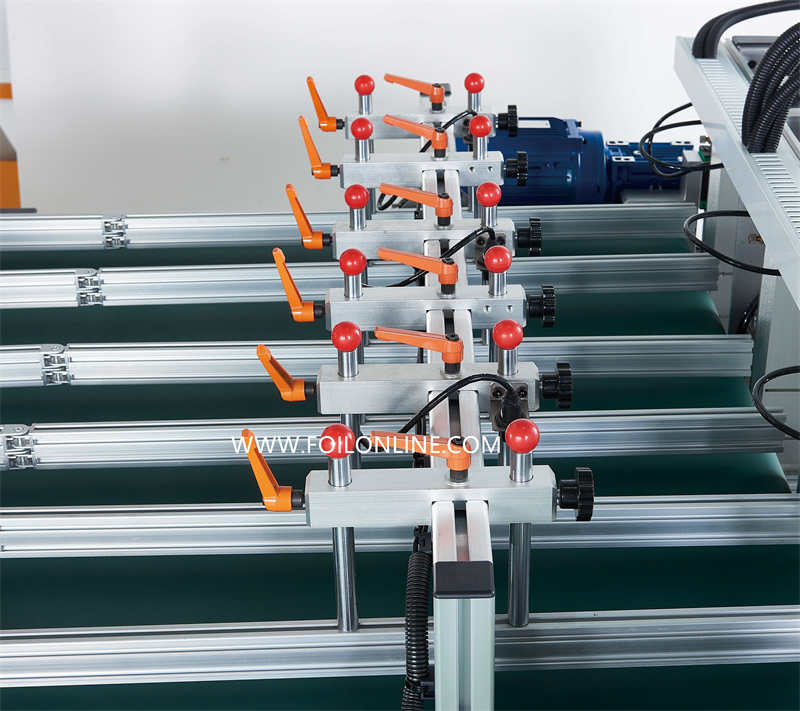

The entire Fully Automatic Aluminium Foil Container Making Machine adopts mechatronics design and the integrated electrical control for feeding and press adopts independent system design, which is safe and anti-interference. The touch screen is hung on the left side of the press, which is easy to operate. The stacker is installed on one side and work independently . The PLC program logic of the entire production line is perfectly matched, which greatly improves the production efficiency of the entire machine, making it more intelligent and humane.

FEATURE

- This production line can work automatically. Worker operates the machine through electric control system and collect the stacked products conveniently.

- Machine can be designed and manufactured according to customer’s requirment and customer’s target price.

- Top Safety and long lifetime,high precision control of feeding step and speed.

- Wet clutch pneumatic punch, long service life, low noise

- The replacement of the mold is convenient and easy to change.

CONFIGURATION

- Auto-lubricated Foil Feeder

- Pneumatic Press for coffee capsule

- Foil container mould

- Capsules Stacker

- System control touch screen

- Foil Scrap System

- Electric cabinet

Production Capacity

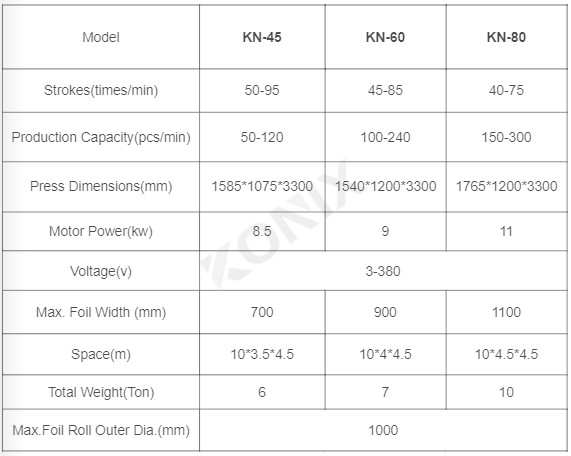

The capacity of production of konix aluminum foil container could vary from 50 – 300 pcs/min

Production Flow of Fully Automatic Aluminium Foil Container Making Machine

- The feeder feeds the material into the pneumatic press.

- The material goes into the mold and is pressed into shape.

- Products are made and blown out

- Products are collected by stacker

TECHNICAL DATA

KONIX provides one-stop solution for aluminum foil container production line including aluminum foil container mould.