Nespresso Coffee Capsule Making Machine

Coffee capsule:

Aluminum foil coffee capsule is used for coffee packing. It’s able to protect the unique aromas and flavours of our coffees – unlike any other material available today.

KONIX Nespresso Coffee Capsule Making Machine

INTRODUCTION

Konix spans more than one decade of visionary design power, effective production ability with continuous improvements to design and manufacture Nespresso coffee capsule making machine for standard type and customized type empty coffee capsule , so help producers win the market by good quality capsules and stable machinery.

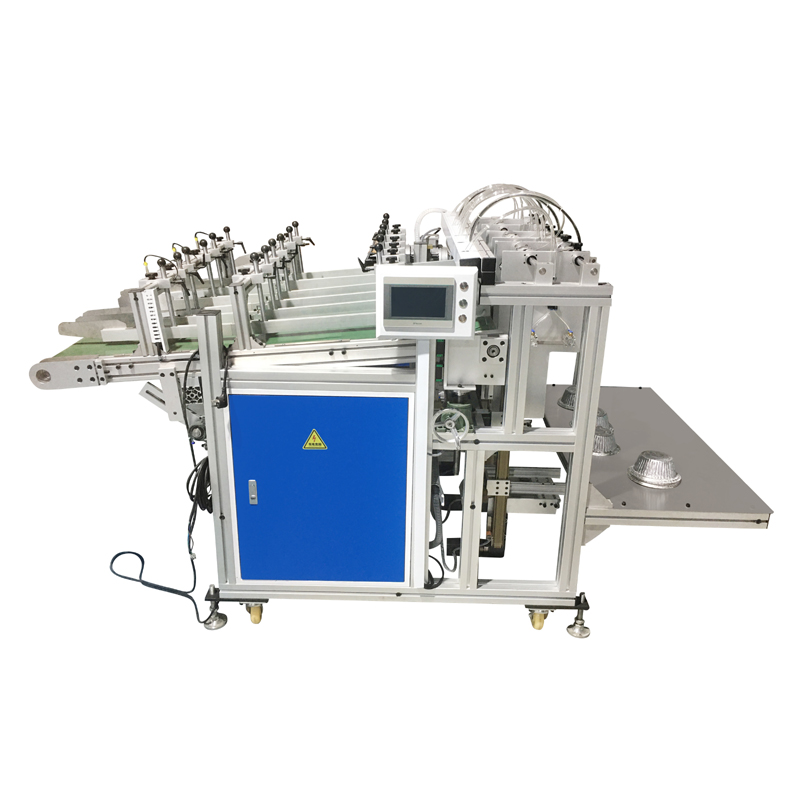

The entire Nespresso coffee capsule making machine adopts mechatronics design and the integrated electrical control for feeding and press adopts independent system design, which is safe and anti-interference. The touch screen is hung on the left side of the press, which is easy to operate. The stacker is installed on one side and work independently . The PLC program logic of the entire production line is perfectly matched, which greatly improves the production efficiency of the entire machine, making it more intelligent and humane.

FEATURE

- The technology is unique and exclusive in China, with the capacity of production of machinery could vary from 6000 pcs/hour.

- This production line can work automatically. Worker operates the machine through electric control system and collect the stacked capsules

- We support optional flange tooth technique which is done once by punch is supported, so as to be used without any ring attached.

- Capsule appearance and technique can be customized on customer request

- Touch screen for the whole production line is equipped to operate the machine easily

- Konix provides coffee capsule glue dispensing machine for making capsule better sealing.

CONFIGURATION

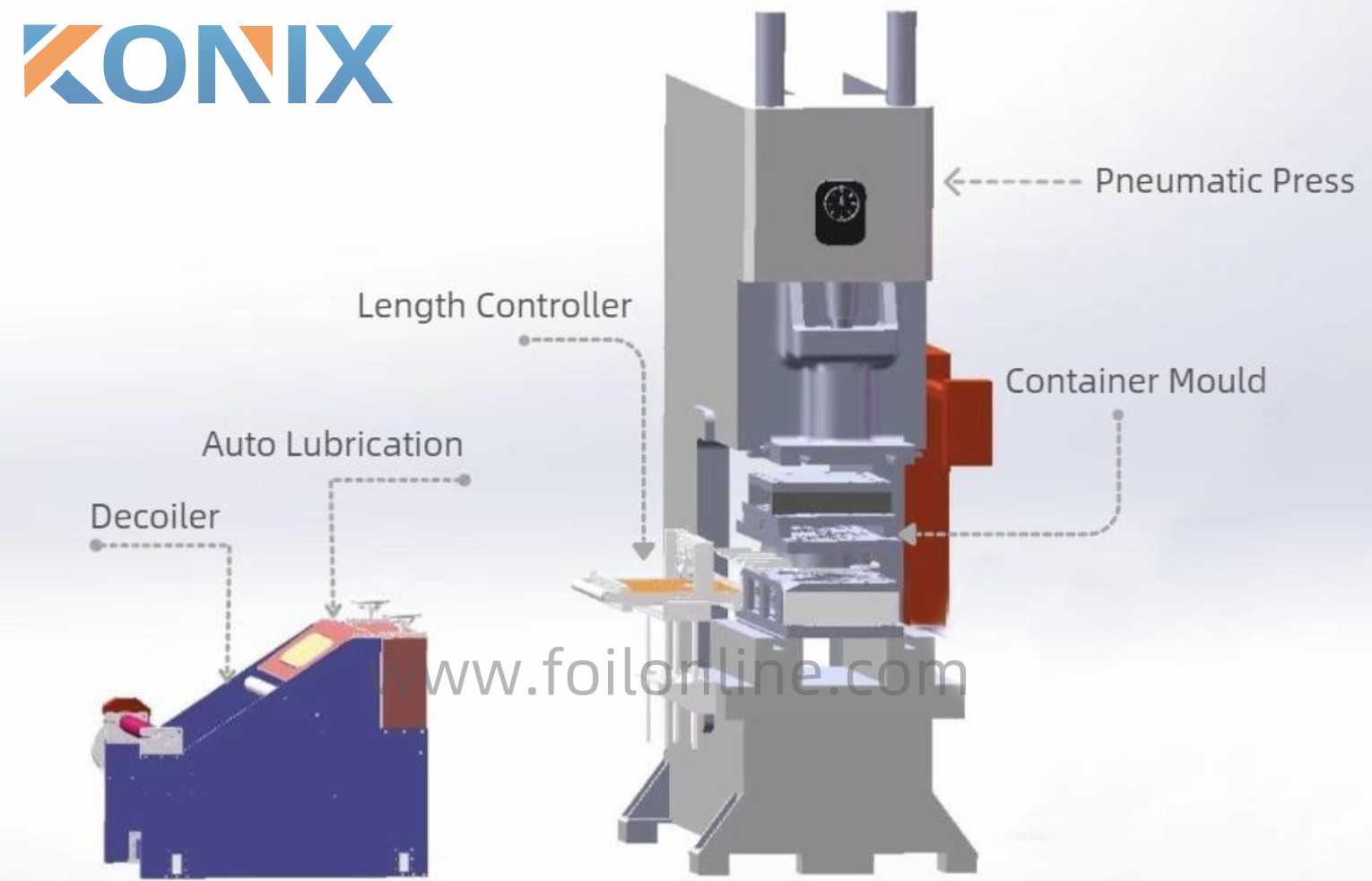

- Auto-lubricated Foil Feeder

- Pneumatic Press for coffee capsule

- High-precision coffee capsule mould

- System control touch screen

- Electric cabinet- Main parts from Inovance, Mitsubishi, Schneider, Siemens

SALES SERVICE

- Overseas machinery service: Our team of engineers is available to provide service and support for machinery overseas, ensuring timely assistance and maintenance.

- Internship and worker training: We offer internship services and can assist in training your workers to operate molds and machines effectively, enhancing their skills.

- Technical assistance: We provide constant technical assistance to support users throughout the installation phases, testing processes, and continuous maintenance of the machines.

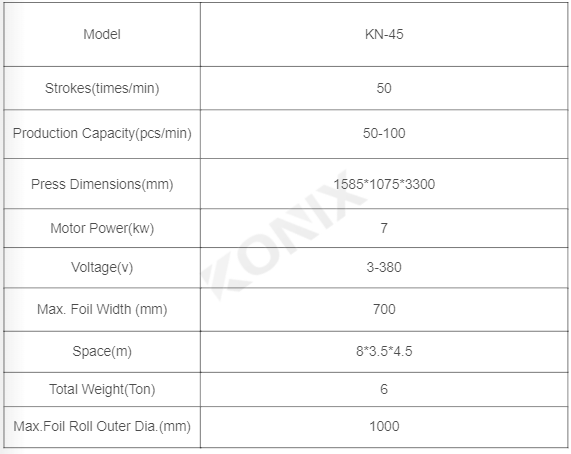

Production Capacity

The capacity of KONIX Nespresso Coffee Capsule Making Machine could be up to 6,000 pcs/hour

Production Flow of Aluminum Coffee Capsule Making Machine

- The feeder feeds the material into the pneumatic press.

- The material goes into the mold and is pressed into shape.

- Products are made and blown out

- Products are transferred by conveyer belt or stacker

TECHNICAL DATA

KONIX provides one-stop solution service for empty aluminum coffee capsule manufacturing: